Fixtures and Their Role in the Mechanical Manufacturing Industry

-

Assembly Jigs and Their Role in the Manufacturing Industry

- Definition:

Jigs are essential technological equipment in the processes of machining, inspection, and assembly of mechanical products. They are used to determine the position of the workpiece in relation to the cutting tool and to securely hold the workpiece in place under the influence of cutting forces during machining.

Functions of jigs:

-

Ensure accurate positioning between the workpiece and the cutting tool.

-

Reduce auxiliary time and machine time.

-

Utilize and expand the technological capabilities of the machine.

-

Reduce workers’ labor intensity.

-

Lower skill level requirements for operators.

Jigs contribute to enhancing the level of mechanization and automation in precision mechanical manufacturing. On machine tools, machining processes always require proper mounting and positioning of workpieces. Therefore, jigs are indispensable equipment in the machining process on metal-cutting machines.

Accordingly, jigs must meet two essential criteria: accurate positioning and secure clamping.

- Classification:

- Assembly jigs

- Inspection jigs

- Machining jigs

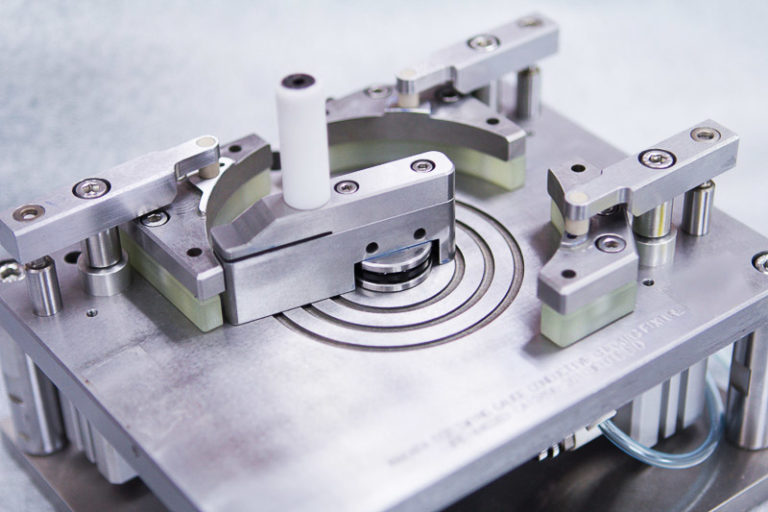

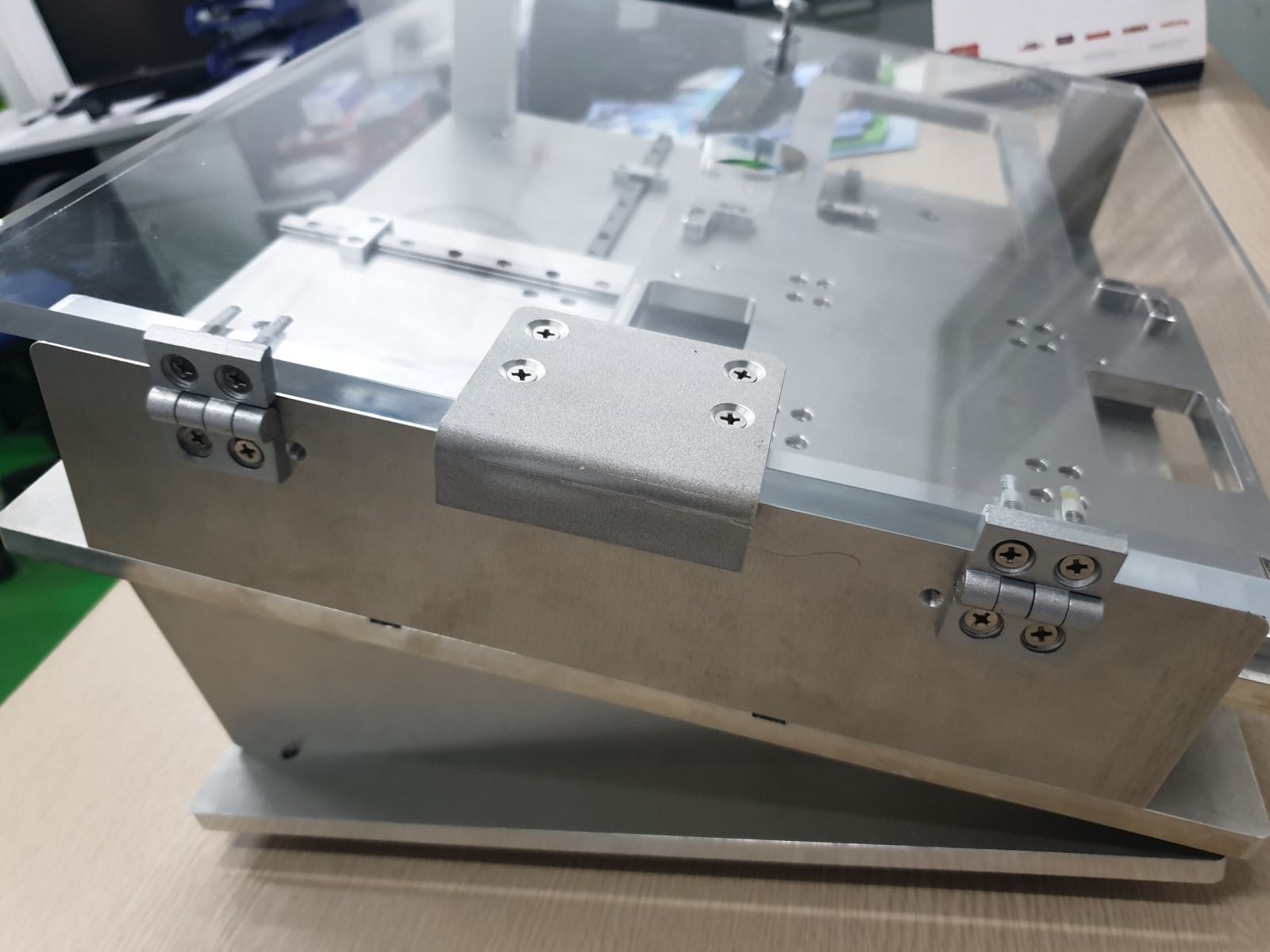

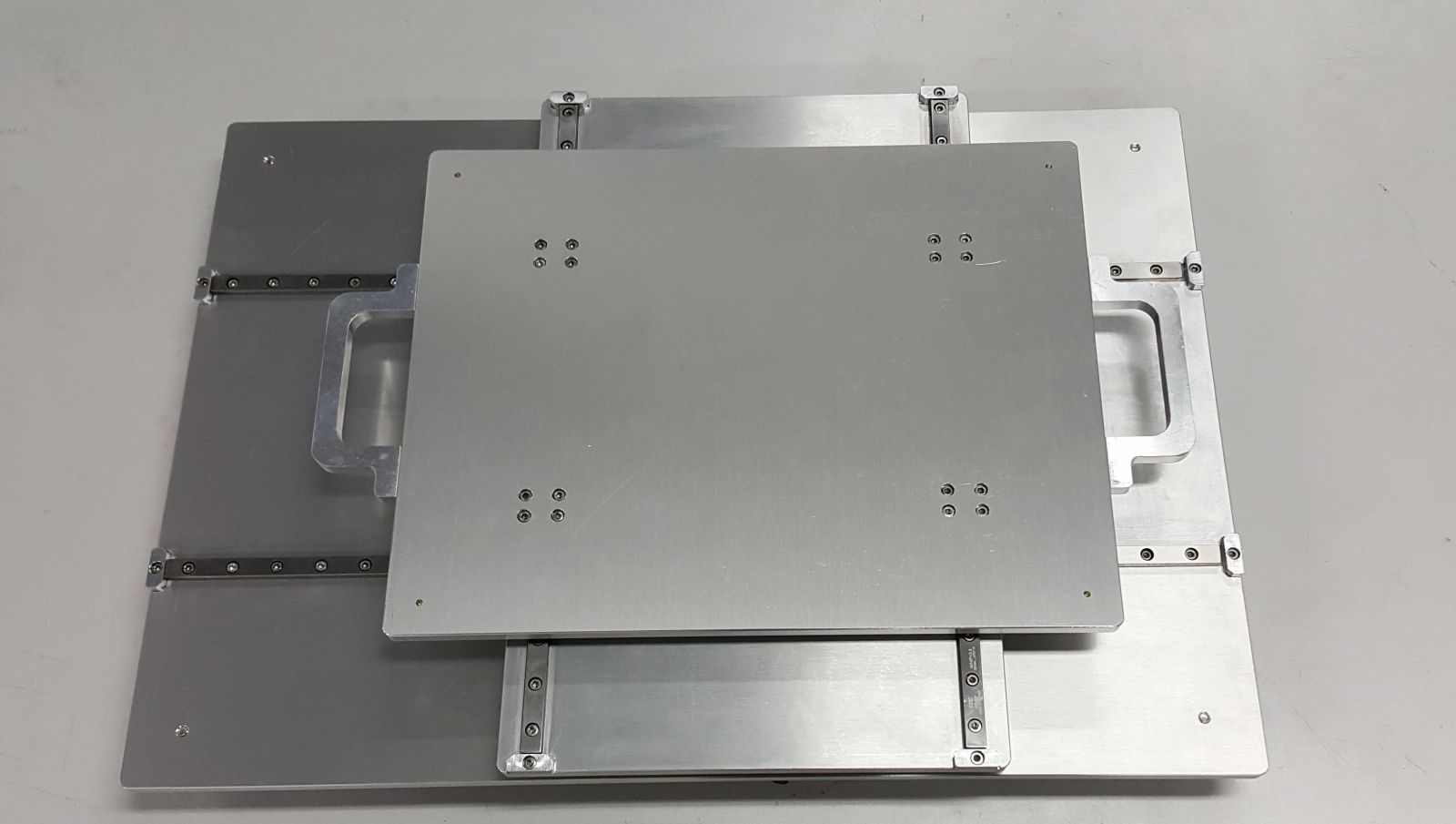

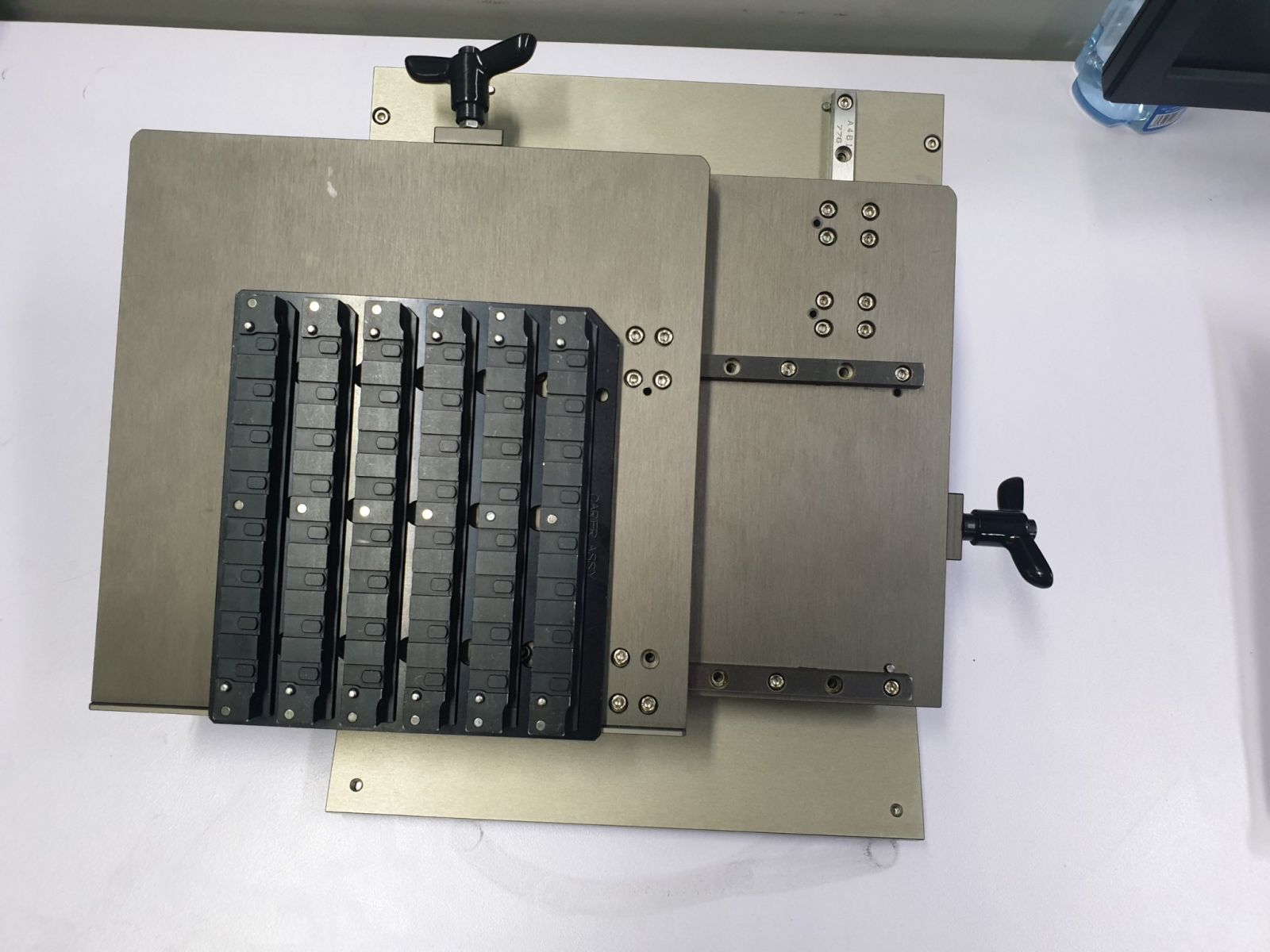

Assembly Jigs

.jpg)

Assembly jigs are fixtures used to position and clamp components (products), including:

- These are commonly used in single-piece production and small-batch manufacturing. They include assembly tables, V-blocks, angle plates, jacks, and various auxiliary components and accessories (such as liners, shims, clamps, etc.).

-

Specialized Assembly Jigs: These are widely used in large-scale and mass production to perform specific assembly operations. Based on their function, they are classified into two types:

-

Jigs for clamping base components

-

Jigs for accurately positioning components

-

Inspection Jigs:

Inspection Jigs: Inspection jigs are used to evaluate the accuracy or surface quality of parts and products during machining as well as in the final product stage.

Errors in parts, typically ranging from 10–20% of the tolerance, may arise from factors such as measurement processes, wear, or temperature. To minimize these technical errors, inspection jigs are designed with careful consideration of the underlying causes.

Inspection jigs are generally classified into:

-

Static inspection jigs (commonly used for small- and medium-sized parts)

-

Mobile inspection jigs (used for inspecting large parts or products)

To improve inspection efficiency, jigs are often designed to allow multiple parameters to be measured in a single setup, or integrated into semi-automatic and automatic devices. The most advanced method is in-process inspection, which enables checking during machining. This approach helps reduce product costs by minimizing defective parts and eliminating the need for separate inspection operations.

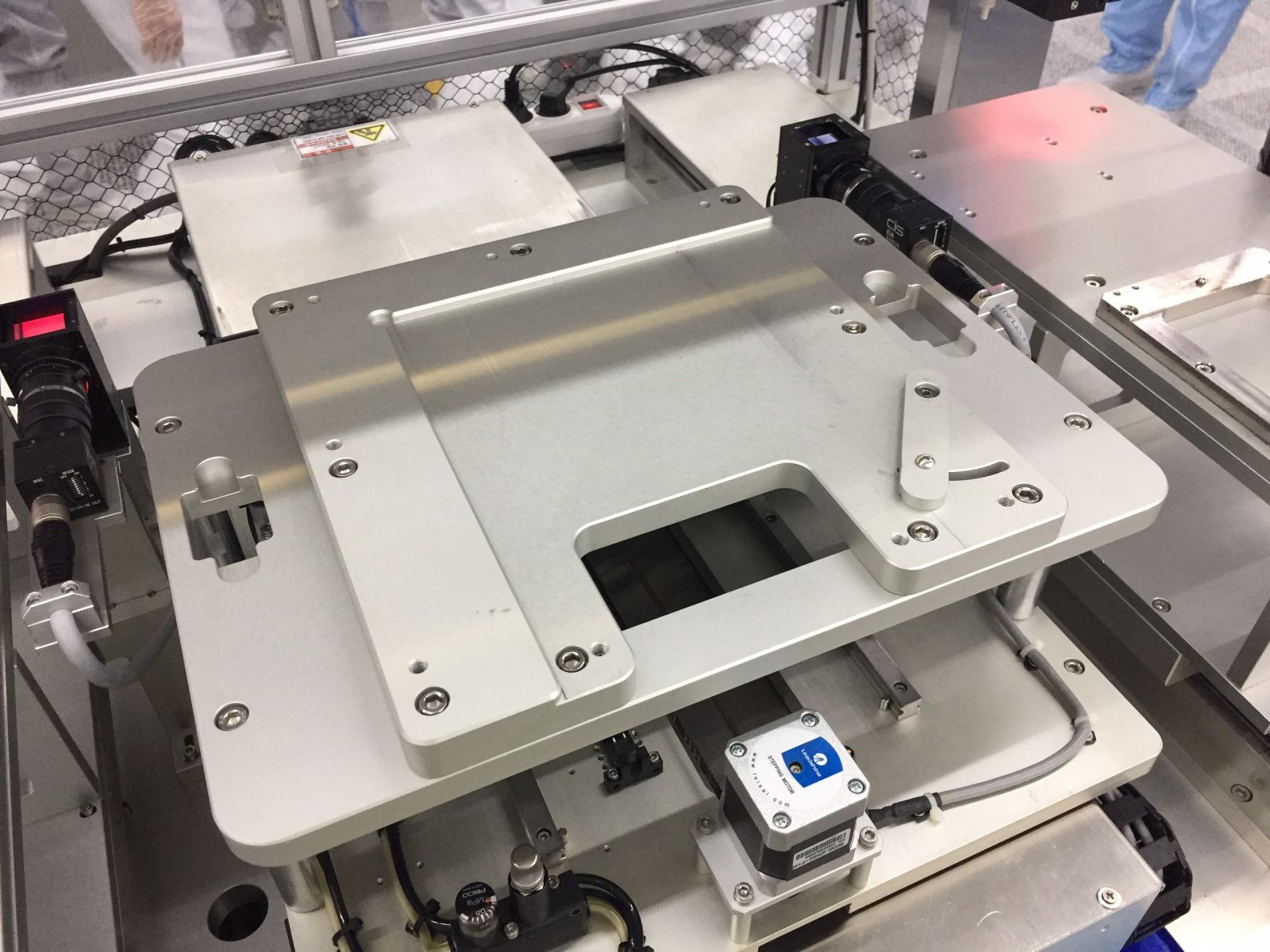

- Machining Jigs:

Machining Jigs:

A machining jig is a technological device designed to accurately determine the position of a workpiece relative to the cutting tool and to maintain that position securely throughout the machining process.

Functions of machining jigs:

-

Ensure positional accuracy of machined surfaces. By using jigs for setup, the relative position between the machined surface, the machine, and the cutting tool can be determined with high accuracy, consistently, reliably, and quickly.

-

Increase labor productivity and reduce auxiliary time. Jigs make it possible to clamp multiple workpieces simultaneously, allowing auxiliary time to overlap with basic machining time. With automated jigs, auxiliary time can be further reduced, significantly improving productivity.

-

Expand the application range of machine tools. Jigs enable machines to process complex surfaces that would otherwise be unachievable without such equipment.

-

Lower skill requirements and reduce manual effort. By simplifying setup and clamping, machining jigs reduce the need for highly skilled workers and lessen physical labor.

- Role in the Mechanical and Manufacturing Industry

Role in the Mechanical and Manufacturing Industry

Although jigs and fixtures are often relatively small components within a machine, they play highly important roles:

- Determine the position and guide the cutting tool.

- Reduce auxiliary time and machine time

- Provide additional motions to machine complex surfaces, thereby utilizing and extending the technological capabilities of the machine

- Reduce workers’ labor intensity

- Lower operator skill requirements while ensuring precise positioning between the workpiece and the cutting tool